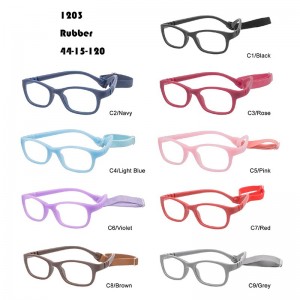

Colorful Baby Optical Frames TPE Eyeglasses W324001

Related Products

Colorful Baby Optical Frames Silicon Eyeglasses W324011

Colorful Baby Optical Frames TPE Eyeglasses W324002

Colorful Baby Optical Frames TPE Eyeglasses W324003

Colorful Baby Optical Frames TPE Eyeglasses W324001

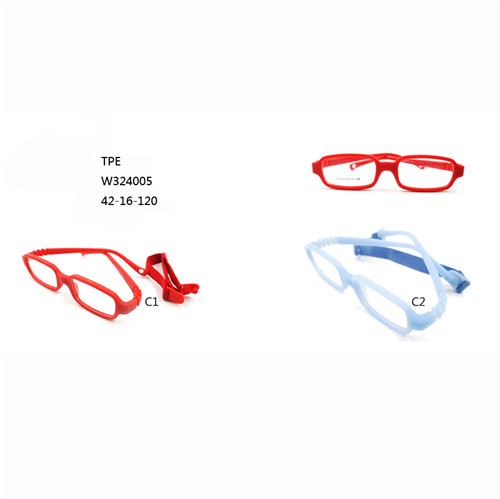

Colorful Baby Optical Frames TPE Eyeglasses W324005

Colorful Baby Optical Frames TPE Eyeglasses W324006

Colorful Baby Optical Frames TPE Eyeglasses W324007

Colorful Baby Optical Frames TPE Eyeglasses W324008

Colorful Baby Optical Frames TPE Eyeglasses W324009

TPE glasses material characteristics

TPE glasses material characteristics TPE is a kind of rubber feel, high elasticity, high strength, high resilience, and can be processed by injection molding, extrusion, casting and calendering, etc. It is safe, environmentally friendly, non-toxic and has a wide range of hardness and excellent coloring. It has excellent properties, soft touch, weather resistance, fatigue resistance and temperature resistance, excellent processing performance, and can be recycled to reduce costs. The waste generated in the production process (escape burrs, extruded waste rubber) and the final waste products can be directly returned for reuse; used TPE old products can be simply regenerated and then recycled, reducing environmental pollution and expanding the source of renewable resources. How to use The following TPE material models are aimed at the use of eye products and the characteristics and advantages brought to the product. one. Model: ES3001G-6 Product: Eye Flank Features: This model material is an improvement of the previous model ES3001G-1, mainly for the yellowing resistance (good UV resistance) of TPE material, which is not easy to yellow. Good molding process, strong rubber feel and high resilience. two. Model: ES5505E Product: Foot Cover, Nose Pad Features: The material has a strong rubber feel. Good molding process. High strength, good tear resistance. Super resilience. three. Model: EB5500SM Product: Black Foot Cover Features: The material has strong rubber feel, good molding process, good strength and good resilience. Because the material is black particles, it reduces the color matching process when customers make black foot cover products. Four. Model: EB3539 Product: goggle frame wrapping Features: The material has strong wrapping force in the fake PC goggle frame, and it is not easy to fall off and open. Good molding process and good resilience. five. Model: TA6589K Product: Adhesive PC frame Features: The material has strong adhesion to PC, ABS and other materials, especially to the PC plastic parts after oil injection. The material (good UV resistance) has good resistance to yellowing under UV light. The material is well formed. Strong resilience. Good scratch resistance.